A Manufacturer-Level Cost Control Guide for Importers, Distributors & Private Label Brands

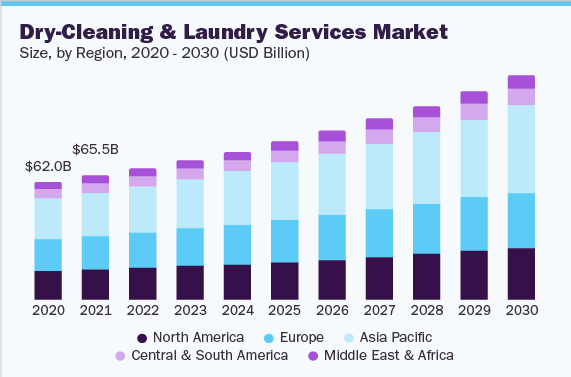

In today’s laundry care market, cost pressure is no longer temporary — it is structural.

Rising raw material prices, unstable freight rates, stricter compliance rules, and retailer margin compression are forcing wholesalers and private label brands to make difficult decisions. Many respond by pushing suppliers for lower prices. Most fail.

Why?

Because cutting price is not the same as reducing cost.

After working with hundreds of laundry product buyers across Europe, North America, and Southeast Asia, one pattern is clear:

the wholesalers who successfully reduce costs by 15–30% do so without touching quality — by redesigning how cost is built into the product.

This article explains how professional B2B buyers reduce laundry product costs without losing quality, using strategies proven at the manufacturing and OEM level.

1. The Biggest Cost Control Mistake: Chasing the Lowest Quotation

The fastest way to destroy margin is to negotiate unit price without understanding cost structure.

At quotation stage, cheaper laundry detergents often look attractive. Problems appear later:

- Higher consumer dosage

- Increased complaints

- Leakage or packaging failure

- Regulatory rework

- Returns and delisting

Experienced wholesalers know that the cheapest supplier often becomes the most expensive one after launch.

Real cost control starts with understanding where money is actually lost — not where it looks expensive on paper.

2. Cost per Wash: The Only Metric That Matters

Professional buyers do not manage cost per bottle or per carton.

They manage cost per wash.

Why cost per wash determines real margin

- Liquid detergents are frequently overdosed

- Inconsistent dosing increases usage by 20–40%

- Retailers and institutions demand predictable performance

How leading buyers reduce cost per wash

- Concentrated formulations

- Optimized surfactant systems

- Pre-measured formats such as laundry pods

- Controlled fragrance release instead of over-perfuming

In OEM projects, manufacturers consistently see that buyers who optimize cost per wash recover margins even when unit prices increase.

3. Formulation Efficiency Beats Ingredient Cost Every Time

Cutting formulation cost by using cheaper raw materials is a short-term illusion.

What actually works is laundry formulation optimization efficiency.

Manufacturer-level optimization methods

- Surfactant balancing instead of higher dosage

- Enzyme systems that work at lower temperatures

- Reduced filler content without performance loss

- Micro-encapsulated fragrance systems for longer scent life

These changes reduce active material waste while maintaining cleaning performance.

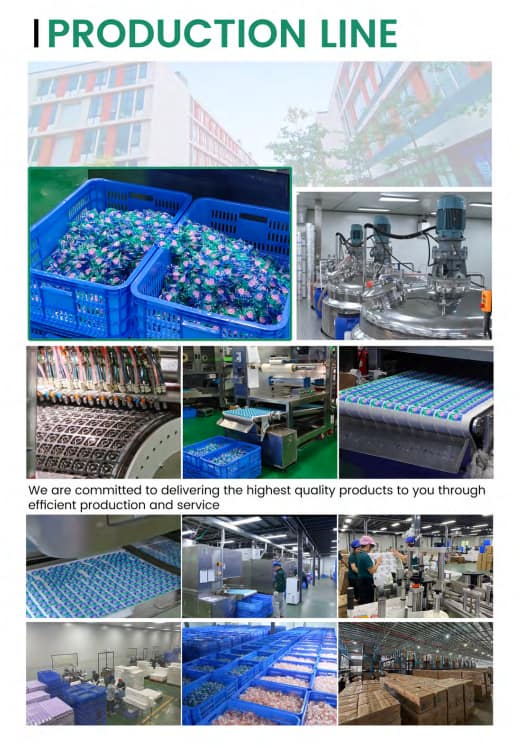

At IKEDA, formulation cost optimization is treated as an engineering task — not a purchasing decision — which is why long-term partners rarely face quality instability after scaling.

4. Concentration: Where Cost Reduction Becomes Structural

Concentration is one of the few cost levers that affects every part of the supply chain.

Why concentrated laundry products lower total cost

- Less water shipped

- Lower freight cost per wash

- Smaller packaging footprint

- Better pallet and container utilization

For export-oriented wholesalers, concentration often stabilizes margins during freight volatility.

This is why concentrated liquids and laundry pods are increasingly preferred in private label programs targeting international markets and export-optimized laundry products.

5. Packaging Is a Cost Lever — Not a Design Detail

Many buyers underestimate packaging as a cost driver.

In reality, packaging impacts:

- Material cost

- Shipping efficiency

- Damage and leakage risk

- Retail handling and storage

Common packaging mistakes

- Oversized bottles with low fill efficiency

- Weak caps leading to transit leakage

- Excessive secondary packaging

Proven packaging cost reductions

- Lightweight but reinforced bottles

- Compact pod packaging designs

- Stackable cartons for export

- Reduced air volume inside packaging

In multiple OEM cases, sustainable packaging efficiency optimization alone reduced landed costs by 10–20%, without touching formulation or quality.

6. Logistics: The Silent Margin Killer

Freight is no longer predictable — and it cannot be ignored.

How logistics destroys margin

- High water content increases shipping weight

- Inefficient packaging wastes container space

- Poor palletization raises handling costs

How professionals control logistics cost

- High-density formulations

- Export-optimized packaging

- Standardized pallet configurations

- Fewer SKU size variations

Laundry pods consistently outperform traditional liquids in logistics efficiency, especially for long-distance exports.

7. Quality Failures Cost More Than Quality Investment

Quality problems are not neutral — they are expensive.

Hidden quality costs include:

- Returns and refunds

- Complaint handling

- Emergency reformulation

- Retailer delisting

- Brand damage

High-risk areas that must be controlled

- Raw material consistency

- Moisture control in pod production

- Film dissolution reliability

- Stability under real shipping conditions

Experienced OEM laundry manufacturers design processes to prevent failures, not react to them.

8. OEM Partner Selection Determines Long-Term Cost Stability

Cost control is not achieved by negotiating harder — it is achieved by choosing better partners.

What strong OEM partners provide

- Proven, stable formulations

- Scalable MOQs for market testing

- Regulatory-ready documentation

- Cost optimization suggestions based on volume growth

IKEDA supports both OEM and ODM laundry programs, allowing B2B buyers to start with validated formulations and gradually customize fragrance, concentration, or packaging as demand grows — without risking early-stage instability.

9. Compliance Errors Are One of the Most Expensive Mistakes

Regulatory issues often appear after production, when correction is most costly.

High-cost compliance risks

- Incorrect labeling

- Missing IFRA documentation

- Market-specific regulation gaps

- Customs clearance delays

Integrating compliance during formulation and packaging design is significantly cheaper than fixing issues after shipment.

10. A Practical Cost Reduction Framework for Wholesalers

Professional buyers follow a structured approach:

Laundry Cost Optimization Checklist

- ✅ Cost per wash calculated

- ✅ Formulation efficiency reviewed

- ✅ Packaging volume optimized

- ✅ Logistics efficiency modeled

- ✅ Quality risks controlled

- ✅ Compliance validated

- ✅ OEM scalability confirmed

Buyers who apply this framework consistently protect margins while competitors struggle with price wars.

Conclusion: Reduce Structural Costs, Not Product Value

Reducing laundry product costs without losing quality is not about sacrificing performance — it is about redesigning how cost is built into the product.

The wholesalers and private label brands that succeed:

- Focus on total cost, not unit price

- Optimize formulation and packaging together

- Use concentration to stabilize logistics costs

- Control quality risks early

- Work with experienced OEM partners

With over 20 years of experience in household cleaning product manufacturing, IKEDA laundry manufacturer supports global B2B partners with laundry solutions designed for cost efficiency, regulatory compliance, and long-term margin growth.