How Advanced Scent Technology Drives Differentiation, Margins, and Long-Term Brand Value

In the premium laundry category, fragrance has quietly evolved from a secondary sensory element into a core commercial differentiator. For private label brands, wholesalers, and retail buyers, scent performance increasingly influences shelf positioning, pricing power, and repeat purchase behavior.

As laundry products become more standardized in cleaning efficacy, micro-encapsulated fragrance technology is emerging as one of the few areas where brands can create measurable, defensible advantages—both technically and commercially.

This article explains how micro-encapsulated fragrance works in laundry products, why it matters for premium positioning, and how B2B buyers should evaluate it as part of a scalable OEM and private label sourcing strategy.

What Is Micro-Encapsulated Fragrance in Laundry Products?

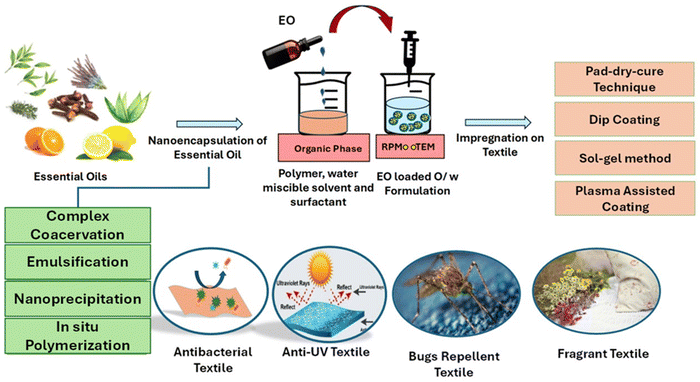

Micro-encapsulated fragrance refers to the process of enclosing fragrance oils within microscopic capsules, typically engineered from polymer-based or biodegradable shell materials. These capsules are designed to remain stable during detergent manufacturing, transportation, and storage, and to release fragrance gradually in response to friction, moisture, or movement.

In laundry applications, this technology enables fragrance release across multiple stages:

- During washing

- During drying

- During fabric wear and handling

From a manufacturing perspective, micro-encapsulation fundamentally changes how fragrance behaves in detergent systems. Instead of evaporating or degrading rapidly, fragrance is protected and delivered in a controlled manner, extending perceived freshness well beyond the wash cycle.

Why Conventional Fragrance Systems Limit Brand Performance

Traditional laundry fragrances are typically added as free oils directly into detergent formulations. While this approach is cost-efficient upfront, it creates structural limitations that premium brands increasingly struggle with.

In large-scale production, manufacturers commonly observe:

- Significant fragrance loss during high-temperature mixing and filling

- Inconsistent scent strength after long-distance shipping

- Rapid scent fade after washing and drying

- Higher variability in consumer feedback across batches

For wholesalers and retail buyers, these technical issues translate into commercial risk—more complaints, weaker brand loyalty, and heavier reliance on price promotions.

Micro-encapsulated studies fragrance addresses these challenges by stabilizing fragrance delivery throughout the entire product lifecycle.

Why Premium Laundry Brands Are Adopting Micro-Encapsulation

1. Longer-Lasting Scent as a Pricing Lever

Consumer research consistently shows that perceived scent longevity strongly influences willingness to pay. In controlled comparisons, laundry products using micro-encapsulated fragrance often deliver 30–50% longer scent perception on fabric compared to conventional fragrance systems.

For retail buyers, this supports:

- Higher acceptable shelf pricing

- Reduced promotional dependency

- Clear differentiation within premium segments

From a wholesale margin perspective, longer-lasting scent helps justify premium positioning without increasing active dosage proportionally.

2. Fragrance as a Brand Signature, Not a Commodity

Scent is one of the strongest sensory triggers for memory. Micro-encapsulation allows brands to develop signature fragrance profiles that remain recognizable throughout product use.

In OEM production, this consistency is critical. Encapsulated systems reduce batch-to-batch variability, helping private label brands maintain a stable sensory identity even as volumes scale.

For distributors, this translates into stronger brand recall and lower substitution risk at retail.

Application Across Laundry Product Formats

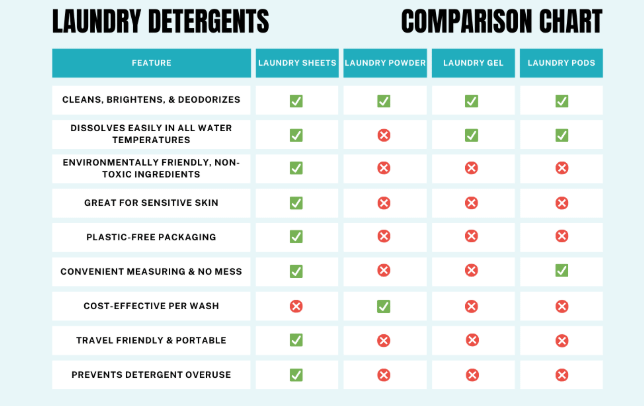

Laundry Pods

Laundry pods benefit significantly from micro-encapsulated fragrance due to their pre-measured dosage and concentrated formulations. Encapsulation protects fragrance integrity even in high-active chemical environments, ensuring consistent release performance.

Liquid Detergents

In liquid laundry detergent manufacturing, high water content and temperature fluctuation during shipping can degrade free fragrance oils. Encapsulation reduces this degradation, improving shelf-life stability—especially for export markets.

Fabric Softeners and Scent Boosters

In fragrance-driven categories, encapsulation is no longer optional. Premium positioning in these segments relies heavily on controlled scent release and long-lasting freshness.

Manufacturers such as IKEDA integrate micro-encapsulated fragrance systems across multiple laundry formats, allowing B2B buyers to maintain consistent scent performance throughout their product portfolios.

Cost Per Wash: The Metric That Matters to B2B Buyers

A common misconception among new buyers is that micro-encapsulated fragrance significantly increases product cost. In practice, professional sourcing decisions are based on cost per wash analysis, not raw ingredient cost.

When evaluated correctly, micro-encapsulation often delivers:

- Lower fragrance dosage requirements

- Reduced fragrance loss during storage and transport

- Fewer post-sale complaints related to scent performance

Over time, this creates a more predictable cost structure and improves margin stability for wholesalers and brand owners.

Compliance and Regulatory Considerations

Micro-encapsulated fragrances used in laundry products must comply with multiple regulatory frameworks, including:

- IFRA fragrance standards

- EU and UK detergent regulations

- Market-specific labeling, laundry industry standards and practices and disclosure requirements

Poorly designed encapsulation systems can lead to compliance issues, residue concerns, or inconsistent release behavior. This is why experienced OEM manufacturers conduct stability testing, release profiling, and regulatory validation before commercial production.

For B2B buyers, regulatory support is not a value-added service—it is a baseline requirement.

OEM & Private Label Customization Opportunities

One of the most strategic advantages of micro-encapsulation is its flexibility. For private label brands, encapsulation enables:

- Signature scent development

- Adjustable release timing (wash-focused vs wear-focused)

- Multi-layer fragrance profiles

- Regional scent customization without full reformulation

At IKEDA, OEM and ODM programs are designed to allow buyers to begin with validated encapsulated fragrance systems and gradually expand into fully customized premium solutions as volumes grow.

This staged approach reduces launch risk while preserving long-term differentiation potential.

Buyer Risk Checklist: What to Evaluate Before Sourcing

Professional buyers should assess micro-encapsulated fragrance systems against several critical risk factors:

- Capsule stability during storage

- Consistency of fragrance release

- Compatibility with detergent base formulas

- Regulatory documentation readiness

- Manufacturing quality control capabilities

Many issues attributed to “encapsulation failure” are in fact the result of insufficient manufacturing control rather than the technology itself.

Strategic Implications for Wholesalers and Distributors

As premium laundry categories expand, fragrance technology increasingly influences which products succeed at retail.

Distributors who understand and communicate the value of micro-encapsulated fragrance position themselves as solution providers, not commodity suppliers—strengthening relationships with both retailers and brand partners.

Conclusion: Scent Science as a Competitive Advantage

Micro-encapsulated fragrance has become a defining element of premium laundry products. It enhances performance, supports premium pricing, and strengthens consumer loyalty—while offering B2B buyers greater control over cost, consistency, and scalability.

For private label brands, wholesalers, and retail buyers, the decision to adopt advanced fragrance technology is no longer optional. It is a strategic choice that shapes long-term competitiveness.

With over 20 years of experience in household cleaning product manufacturing, IKEDA supports global B2B partners with laundry solutions that combine advanced fragrance science, regulatory compliance, and scalable OEM/ODM expertise.

In a market where cleaning performance is increasingly standardized, fragrance technology is becoming the silent differentiator that defines premium brands.